Product Overview

AntiMastitor is a patented, scientifically validated device that protects milk yield instantly after milking.

Product Overview

AntiMastitor is a patented, scientifically validated device that protects milk yield instantly after milking.

Global Challenge

Mastitis: The Costliest Disease in the in Dairy Farming

Mastitis is the most costly disease in dairy farming. It reduces milk yield and quality, increases veterinary costs, and often leads to premature culling of cows. Across Europe, mastitis causes billions of euros in economic losses every year, making it the single most significant challenge for dairy farmers.

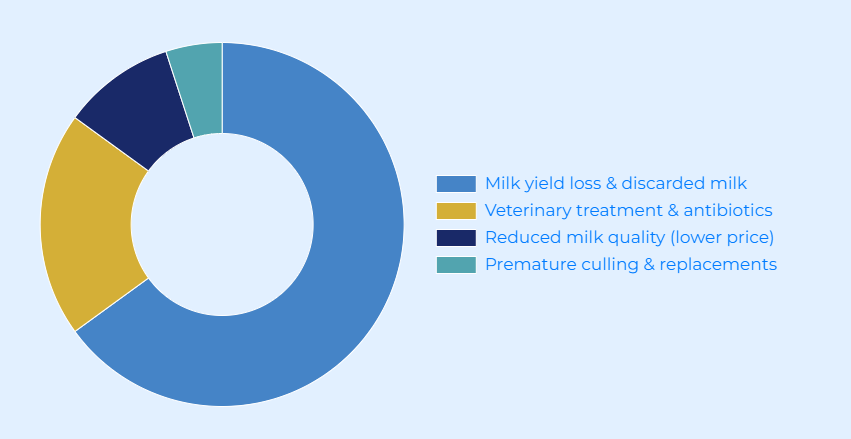

Economic Burden of Mastitis

The economic burden of mastitis is driven mainly by milk yield losses and discarded milk, which account for nearly two-thirds of the total costs. Veterinary treatments, reduced milk quality, and premature culling add to the financial impact, but it is the direct loss of milk production that makes mastitis the most expensive disease in dairy farming. This distribution underlines why prevention technologies are essential for protecting both profitability and sustainability in the dairy sector.

Somatic Cell Count and Milk Quality

Somatic cell count (SCC) is the key indicator of udder health and milk quality. Healthy milk contains fewer than 200,000 cells per milliliter, while the European Union legal threshold is set at 400,000 cells/ml. In mastitis cases, SCC often exceeds 1,000,000 cells/ml, leading to significant quality loss and reduced market value. Lowering SCC is therefore essential for both animal health and the profitability of dairy production.

The AntiMastitor Solution

After milking, the teat canal remains physiologically open for approximately 2–3 hours. During this period, the sphincter muscles are relaxed, and the keratin plug that normally seals the teat canal is absent. This open state creates a critical infection window, as bacteria from the environment can easily penetrate into the udder and cause mastitis.

AntiMastitor addresses this problem through a dual mechanism. First, the teat is immersed in an antiseptic solution that disinfects the teat surface, reducing bacterial load. Second, the device applies controlled low-frequency electrical stimulation (1–100 Hz, maximum 7 mA) to the teat tissue. This stimulation activates the teat sphincter muscles, inducing immediate contraction and closure of the canal.

Clinical trials and ultrasonography studies confirmed that this process reduces the normal 2–3 hour risk period to just a few seconds. By sealing the teat canal almost instantly after milking, AntiMastitor prevents pathogen entry, lowers the incidence of mastitis, and helps maintain milk quality by keeping somatic cell counts (SCC) within safe limits.

Easy Application in Four Simple Steps

AntiMastitor is designed for daily farm use. The application process is quick, simple, and takes only 3 seconds per teat.

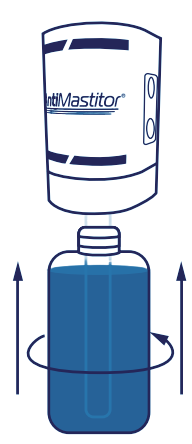

Fill

The device bottle is filled with an antiseptic solution. This ensures that each teat is disinfected during application, providing a hygienic start to the process.

Attach

The filled bottle is securely attached to the device, and the power switch is turned on. AntiMastitor is now ready for immediate use.

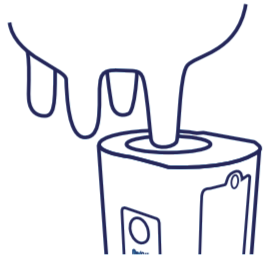

Dip

Each teat is dipped into the antiseptic solution for just 3 seconds. At the same time, low-frequency electrical pulses stimulate the teat muscles and close the canal instantly.

Discard

After all teats are treated, the remaining solution is safely discarded. This keeps the process clean, efficient, and ready for the next milking.

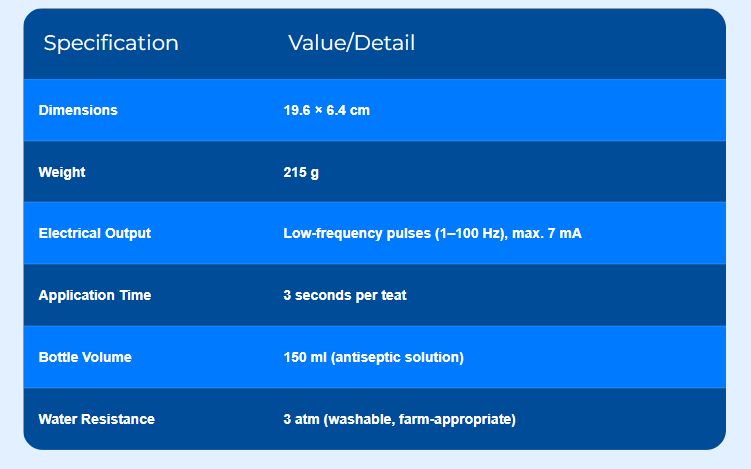

Technical Specifications

AntiMastitor is compact, durable, and designed for daily use in dairy farms. Its technical specifications highlight both ease of application and reliability under field conditions.

|

Specification

|

Value/Detail

|

|---|---|

|

Dimensions

|

19.6 × 6.4 cm

|

|

Weight

|

215 g

|

|

Electrical Output

|

Low-frequency pulses (1–100 Hz), max. 7 mA

|

|

Application Time

|

3 seconds per teat

|

|

Bottle Volume

|

150 ml (antiseptic solution)

|

|

Water Resistance

|

3 atm (washable, farm-appropriate)

|